Life Cycle Assessment

Area: Design, planning and building

Life Cycle Assessment (LCA) is a standardised method to comprehensively quantify environmental impacts caused by the production of goods and services, which can be used to inform decision-making in building design. Measurable indicators include Global Warming Potential (GWP), acidification, eutrophication, and water use to name a few (European Commission, 2010). LCA can be used to account for all input and output flows related to the entire building life cycle, from raw material acquisition, manufacture, use and maintenance (e.g. while the building is occupied), to the deconstruction and beyond End-of-Life phase (Sartori et al., 2021).

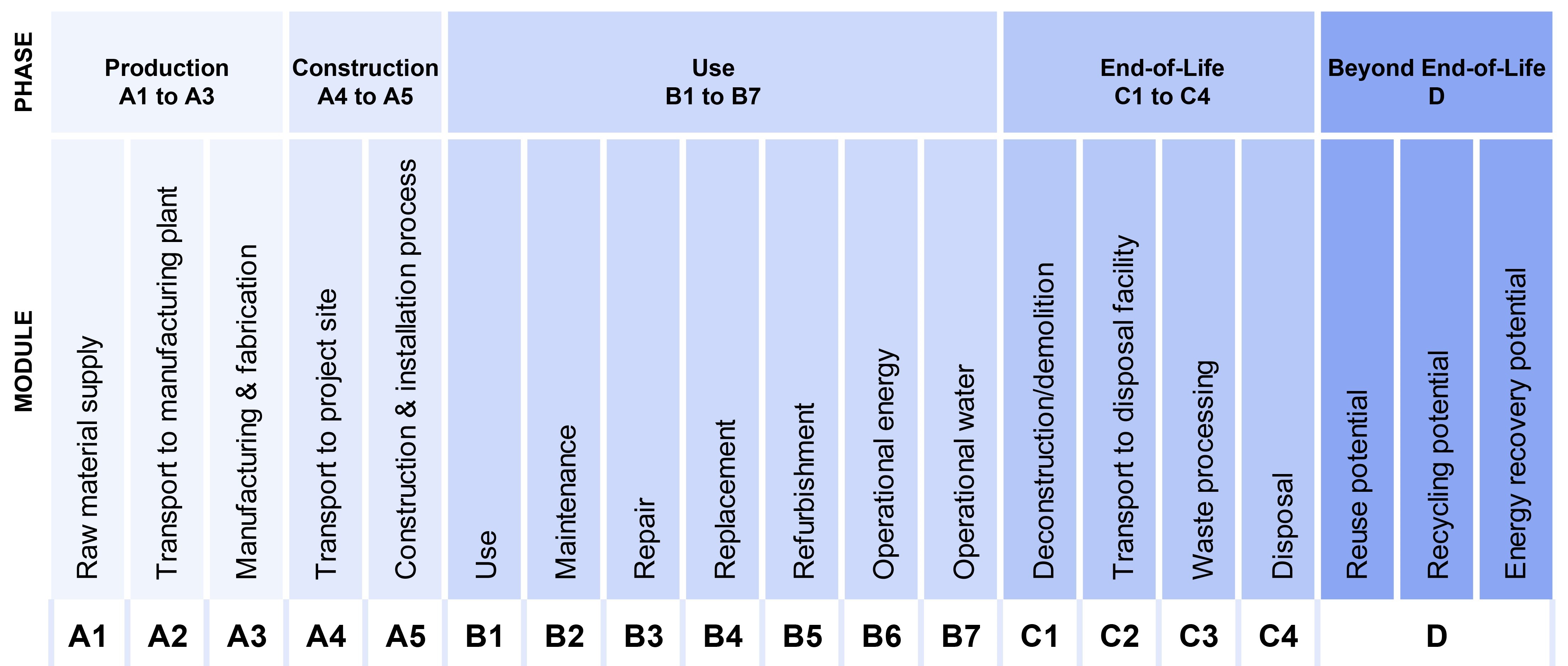

Calculating an LCA requires information for building products and processes usually found in the Bill of Quantities, which includes the type of material and its density combined with the amount of material, measured in either volume or area. The European standard EN 15978 (2011) provides guidance for the calculation method, which breaks down the life cycle into phases A to D, these are: A Production and Construction, B Use, C End-of-Life, and D Beyond End-of-Life. It should be noted however, that it is difficult to compare different buildings using LCA, as methodologies and assumptions vary, impacting results (Ramboll, 2023). An LCA that includes stage D is known as a ‘cradle-to-cradle’ assessment, this supports a circular approach and considers scenarios relating to the building after its ‘useful service life’. It is crucial for stakeholders to consider the beyond End-of-Life impacts when planning and designing housing to support the circular economy transition, primarily through promoting future material reuse.

LCA is an increasingly relevant component of sustainability assessments for buildings following demand for transparency from the construction industry and trends in performance-based design (Sartori et al., 2021). The LCA method has been incorporated into the European Level(s) framework (Dodd & Donatello, 2020), and BREEAM and LEED assessments. The European Commission advocates for LCA, describing it as the "best framework for assessing the potential environmental impacts of products" (European Commission, n.d.). LCA therefore plays an increasingly prominent role in supporting EU policy and meeting the ambitions of the European Green Deal and related initiatives, such as the Circular Economy Action Plan (European Commission, 2020). At the national level, several European countries utilise LCA to regulate embodied carbon, with other countries expected to follow suit in the coming years (Röck et al., 2022).

References

Dodd, N., & Donatello, S. (2020). Level(s) indicator 1.2: Life cycle Global Warming Potential (GWP). https://susproc.jrc.ec.europa.eu/product-bureau/sites/default/files/2020-10/20201013%20New%20Level(s)%20documentation_Indicator%201.2_Publication%20v1.0.pdf

EN 15978. (2011). Sustainability of Construction Works. Assessment of Environmental Performance of Buildings. Calculation Method. European Committee for Standardization.

European Commission. (n.d.). European Platform on LCA | EPLCA: About us. Retrieved May 29, 2024, from https://eplca.jrc.ec.europa.eu/aboutUs.html#:~:text=The%20EPLCA%20fosters%20LCA%20as,Chemical%20Strategy%2C%20and%20many%20more.

European Commission. (2010). ILCD Handbook - General Guide for Life Cycle Assessment: Detailed Guidance (1st ed.). Publications Office of the European Union.

European Commission. (2020). First Circular Economy Action Plan. https://ec.europa.eu/environment/topics/circular-economy/first-circular-economy-action-plan_es

Ramboll. (2023). Comparing differences in building life cycle assessment methodologies. https://www.ramboll.com/en-gb/insights/decarbonise-for-net-zero/which-life-cycle-assessment

Röck, M., Sørensen, A., Steinmann, J., Le Den, X., Lynge, K., Horup L., H., Tozan, B., & Birgisdottir, H. (2022). Towards Embodied Carbon Benchmarks for Buildings in Europe – Facing the data challenge. https://doi.org/10.5281/zenodo.6120522

Sartori, T., Drogemuller, R., Omrani, S., & Lamari, F. (2021). A schematic framework for Life Cycle Assessment (LCA) and Green Building Rating System (GBRS). Journal of Building Engineering, 38, 102180. https://doi.org/10.1016/j.jobe.2021.102180

Created on 30-09-2024 | Update on 23-10-2024

Related definitions

BIM

Area: Design, planning and building

Created on 16-02-2022 | Update on 23-10-2024

Read more ->Life Cycle Costing

Area: Design, planning and building

Created on 05-12-2022 | Update on 23-10-2024

Read more ->Design for Disassembly

Area: Design, planning and building

Created on 18-10-2023 | Update on 23-10-2024

Read more ->Industrialised Construction

Area: Design, planning and building

Created on 09-11-2023 | Update on 23-10-2024

Read more ->Environmentally Sustainable Social Housing

Area: Design, planning and building

Created on 19-06-2024 | Update on 23-10-2024

Read more ->Circular Economy

Area: Design, planning and building

Created on 30-09-2024 | Update on 23-10-2024

Read more ->Related cases

WikiHouse: South Yorkshire Housing Association

Created on 16-10-2024